When I was 16 years old, diving in Greece in what I expected to be crystal-clear waters, I encountered something that would change the trajectory of my entire life. Instead of the vibrant marine life I expected to see, I found myself swimming through more plastic bags than fish. That moment sparked a simple but nagging question: “Why can’t we just clean this up?”

What began as teenage curiosity evolved into The Ocean Cleanup, a nonprofit that I founded at 18 with nothing but €200 of saved pocket money and an unwavering belief that the impossible could become possible. My approach has always been to start simple, iterate relentlessly, and let mission, not technology guide our engineering decisions. What I now recognize as “constraints-driven thinking”, is also the philosophy that guides the mission of The Ocean Cleanup:

The Ocean Cleanup’s mission is straightforward: rid the world’s oceans of plastic.

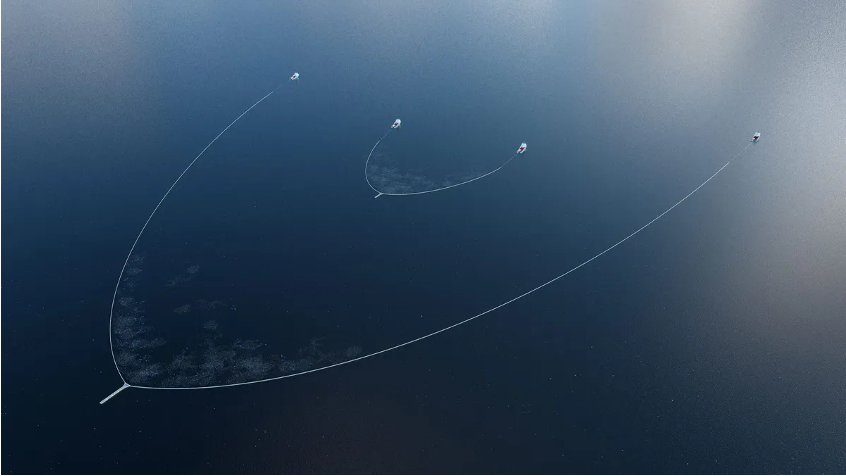

Starting with constraints, not capabilities

My journey into frugal engineering began not in a classroom, but in those waters off Greece, where I first grasped the magnitude of what we were facing. When I returned home to Delft, in the Netherlands, and began researching the problem, I was shocked by what I discovered: a total of 1.8 trillion pieces of plastic were estimated to be floating in the Great Pacific Garbage Patch (GPGP), an area twice the size of Texas, polluting our oceans. Research has shown that of the 900 marine species known to encounter ocean debris, plastic accounts for 92% of these encounters. Even more concerning, 17% of these plastic-affected species are listed as threatened on the International Union for Conservation of Nature (IUCN) Red List of Threatened Species. More shocking still was the scientific consensus that cleaning the oceans was essentially impossible. The conventional approach involving a fishing boat with a net to trawl the oceans would require thousands of years and tens of billions of dollars to clean up just the GPGP. But I remember thinking, “Why move through the oceans when the oceans can move through you?” This insight led to my concept: create an artificial coastline in the middle of a gyre that would passively concentrate plastic so it could be extracted.

When I started studying aerospace engineering at Delft University of Technology, this idea stayed with me. Six months into my studies, I then made the decision that would define my life: I dropped out to pursue this vision full-time.

I spent months in what I can only describe as a state of perpetual frustration. Trying to get sponsorship, to get someone to see my vision, was disheartening. No one was interested. One day, I remember reaching out to 300 companies. I sent out so many emails to try and get this off the ground but just couldn’t get any traction. Only one replied. They told me to go back to school.

However, I did manage to secure a slot to speak at TEDxDelft 2012 and was the first person on stage. My presentation was well received by the audience but at the time there was no impact beyond the auditorium.

The moment everything changed

Then something happened on March 26, 2013. My TEDx talk from 2012, “How the Oceans Can Clean Themselves”, suddenly went viral. The video was picked up by several news sites, from which it spread to hundreds of thousands of people in a matter of days. This momentum allowed me to recruit an initial team and raise our first $90,000 through crowdfunding. That’s how The Ocean Cleanup truly began. With this money I was able to hire a skeleton staff and rent an office. I then started to reach out to researchers on the topics I felt needed to be covered by a broad-scope Feasibility Study, including engineering, oceanography and recycling. A volunteer team of close to 100 scientists and engineers then spent a year working remotely as a virtual team to complete the 528-page study, which was published in June 2014.

What I learned from that experience was invaluable for everything that followed: the ability to engage people and make them passionate enough to want to contribute to the cause. The first crowdfunding round also taught me that I needed to fully develop my pitch to potential funders which I worked on with the help of a funding and finance veteran.

The art of incremental improvement

In 2018 we launched our first ocean plastic removal system, sailing out of San Francisco, with high expectations. We, rather boringly, and in lack of a better naming structure, called our ocean cleaning gizmos “System”, followed by a serial number. The evolution from System 001, via System 001/B to System 002 to System 03 exemplifies what I believe is the essence of frugal architecture: iterative refinement over revolutionary replacement. Each system built upon lessons learned from its predecessor, but the improvements were strategic rather than simply bigger or more complex.

-

System 001, which we nicknamed “Wilson,” faced significant challenges that could have derailed the entire project. The building of System 001 took approximately half a year, built on design, engineering and preparations that started around two years before. After deployment in the GPGP in September 2018, various tests were performed, and “normal operations” were started. System 001 lasted just over three months; a part of the main structural HDPE floater pipe broke off. In addition, the system struggled with plastic retention—debris would flow in as designed but then flow back out again. We learned that plastics behave differently from what we expected before commencing offshore operations. Rather than scrapping the concept, we embraced what I call “focus, fail, and forbear” with a smaller modular set-up in System 001/B. We methodically tested different configurations, ultimately discovering that slowing down the system with a parachute anchor allowed natural winds and waves to push plastic into our collection zone more effectively than any solution powered by wind or waves.

-

System 002 (a.k.a. “Jenny”) proved our concept could work at scale, extracting 282,787 kilograms of trash while covering an area equivalent to nearly 1.5 million football fields. But the real achievement wasn’t the tonnage collected—it was the operational knowledge we gained about everything from weather patterns to marine life interactions.

-

System 03, among the insiders also fondly known as “Josh”, represents our most significant leap in frugal innovation. Nearly three times larger than its predecessor, it can sweep an area the size of a football field every five seconds at peak efficiency.

To demonstrate our belief in the increase in impact, we took one digit out of the serial number. After all, at this performance we would not need three digits to count to full-scale operation. Yet the system’s true innovation lay not in its size but in its smarter design: deeper screens to catch subsurface plastic, 16 underwater cameras for marine life monitoring, and the Marine Animal Safety Hatch (M*A*S*H) that could be remotely triggered to create escape routes for any wildlife that accidentally entered the retention zone.

We have always approached challenges from the position that to solve a problem, you first need to understand it. Therefore, since the early days of the program, we have put a tremendous amount of work into data collection. This has included data on where the pollution is, and how it moves – both through the ocean as well as in rivers. The route from taking physical samples to camera detection and identification of plastics in the water to then develop models that can help us predict and be better equipped to tackle the problem, has been a decade-long journey, as AI has increasingly become a core tool to further our mission.

AI as a force multiplier, not a silver bullet

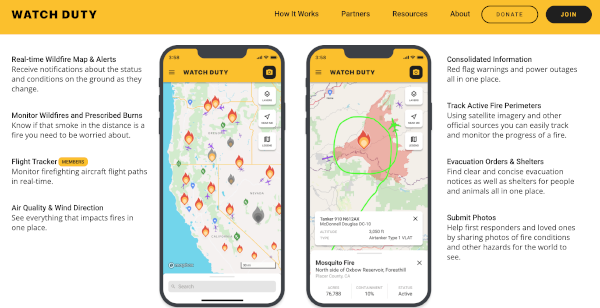

Our approach to AI exemplifies how I deploy emerging technologies as practical tools that dramatically improve operational efficiency. Our Automated Debris Imaging System (ADIS) showcases this philosophy perfectly. Rather than building expensive dedicated research vessels for plastic detection, ADIS leverages merchant ships, cruise liners and even sailing yachts taking part in regattas. First introduced in 2021 as a prototype using GoPro cameras and a YoloV5 object detection model, the system now uses AI-powered cameras that process images, locally, in real-time. Although the ADIS camera is a custom-made product, it is designed to be affordable and easy to lend to partnering ship owners. Thanks to its ease of deployment, 30,000 square kilometers of ocean surface have already been scanned, and a collated dataset and world map are nearing publication.

ADIS only stores critical metadata such as coordinates, object type and size of detected debris rather than uploading massive image files. This approach cuts 99.975% of data transmission costs by reducing the data footprint from approximately 2TB of raw photos to just 500MB of preprocessed data per month per camera, while enabling continuous monitoring across vast ocean areas that would cost us millions of dollars in fuel and crew hours to survey using traditional methods. This way, ADIS is frugal in two ways: by 1/ leveraging existing ships, and 2/ by maximizing the compression and value of the data it transfers.

This pragmatic use of AI extends to our predictive modeling capabilities. By integrating oceanic currents, wind patterns, and historical data, our systems can forecast where plastic accumulations are likely to occur, allowing cleanup operations to target hotspots rather than conducting random sweeps. Weather data, based on satellite data assimilation, is obtained from open-source providers and higher resolution oceanic current models are being investigated to leverage data fusion through a dedicated AI model, in collaboration with AWS. A cloud-based, in-house advection model provides tailored plastic density maps. The result is a dual improvement: our models function like weather forecasts for plastic, directing limited resources where they can have maximum impact, while our AI simultaneously monitors for endangered marine life like sea turtles, helping protect vulnerable species during cleanup operations.

The economics of environmental impact

Perhaps nowhere is my commitment to frugality more evident than in our relentless focus on cost per kilogram of plastic removed, one of our most valued key performance indicators. Although we could technically already clean up the GPGP with a fleet of our current systems, scaling up now wouldn’t be cost competitive with our river operations, so we will have to continue to improve the efficiency of our tech first, before we scale.

Economic constraints have driven some of our most innovative decisions. The cost of removal will always be such that our catch is way too expensive when compared to the regular market value of recycled plastic, and even more so in comparison to new, or virgin plastic. We’ve pursued multiple strategies to improve this economic equation. Our catch management program transforms collected plastic into valuable products, with our The Ocean Cleanup® sunglasses serving as proof of concept for our trash-to-treasure model.

By building our brand and offering the material to be used under a trademark license, however, we find partners willing to help cover operational costs. But more importantly, we’ve focused on operational efficiency improvements that reduce the fundamental cost structure rather than simply finding new revenue streams.

From the testing and operation of System 001 and 001/b we learned that although the system was designed to be fully passive, we’d need many vessels to support the cleanup operations. It would be necessary to frequently sail to the free-floating passive cleanup systems with vessels to extract the collected plastics, and also to tow them back into the GPGP in case they drifted out of the plastic-concentrated areas.

Through extensive modeling and analysis we found that pivoting to an actively propelled system (counterintuitively) resulted in a reduced need for vessel operations: there was no need for towing systems back, extractions could be done by vessels already connected to the systems, and, because we could actively steer the direction of the cleaning systems, this enabled the targeting of more plastic-dense hotspots within the patch.

By expanding our collection systems while maintaining the same vessel count, we can sweep larger ocean areas in the same timeframe, significantly reducing the number of vessels needed per square kilometer of cleaned ocean. System 03’s larger size isn’t about collecting more plastic per system; it’s about reducing the number of vessels needed per area covered.

The cost of ocean cleanup is primarily driven by the number of vessels needed, so our focus has been on limiting vessels required per area covered. This insight has shaped our ocean cleanup design decisions, from system size optimization to automated monitoring systems that reduce crew requirements, and the development of a steering strategy to target plastic-dense areas. However, we’ve learned that different environments demand different solutions: while active vessel systems are crucial for ocean cleanup, passive collection systems often prove more efficient for river operations.

Building for the mission, not the technology

Our Interceptor program is currently focused on 30 cities, ultimately targeting 1,000 rivers, or about 1% of all rivers worldwide by 2040, which combined are responsible for nearly 80% of ocean-bound plastic pollution. Rather than designing a one-size-fits-all solution, we’ve developed a family of systems; Interceptor Original, Interceptor Barricade, Interceptor Barrier + Interceptor Tender, and Interceptor Guard—each configuration is optimized for specific river conditions and throughput requirements.

The Interceptor design philosophy mirrors our ocean systems: leverage natural forces, minimize operational complexity, and optimize for unattended operations wherever possible. Each river deployment includes Environmental and Social Impact Assessments (ESIAs) and Environmental & Social Management Plans (ESMPs) to ensure operations integrate effectively with local ecosystems and communities. This comprehensive approach reflects my belief that technical success means nothing without environmental and social sustainability.

Scaling frugal innovation globally

The Ocean Cleanup’s current operations span from the GPGP to 20 rivers across nine countries: Indonesia, Malaysia, Guatemala, Jamaica, Thailand, Panama, U.S.A., Dominican Republic, and Vietnam. This represents the early phase of our ambitious 2040 goal.

This global reach required us to develop what I call “frugal operations”—standardized systems that can be deployed and maintained locally without requiring teams of specialized engineers for each installation. Our River Monitoring Systems, timelapse camera and other remote sensor technologies and systems exemplify this approach. We’ve hopefully simplified the camera workflow so much that we can just send it with instructions, shifting more to external partners for self-installation.

This operational model reflects a key principle I’ve learned: design for maintenance and scalability from day one. By creating systems that can be deployed, operated, and maintained by local partners, we’ve removed ourselves as a bottleneck to global expansion while reducing operational costs and building local capacity.

Lessons for frugal architects everywhere

My journey with The Ocean Cleanup offers several key insights for organizations facing seemingly impossible technical challenges:

Start with the constraint, not the solution. Our passive collection approach emerged from accepting that active plastic collection would be prohibitively expensive, leading us to harness natural ocean forces instead of fighting against them.

Measure what matters most. Our focus on cost per kilogram of plastic removed drives every engineering decision, ensuring that efficiency improvements translate directly to mission impact.

Iterate with purpose. Each system generation addressed specific operational lessons rather than simply scaling up, resulting in compound improvements over time.

Use technology as a tool, not a goal. Our AI implementations aim to solve specific operational problems, mapping plastic hotspots, reducing research costs, automating monitoring, rather than showcasing technological sophistication.

Do no harm. Each system is designed so that there is no negative impact on the marine environment.

Design for global deployment from day one. By creating systems that can be operated by local partners, we’ve built a scalable operational model that reduces costs while building local capacity.

The path forward. As I reflect on our journey from that moment in Greek waters to where we stand today, I’m struck by how constraints have been our greatest teacher. We’ve removed over 93.5 million pounds of trash from aquatic ecosystems worldwide, including more than one million pounds from the GPGP alone, representing 0.5% of the total accumulated trash there.

But perhaps more importantly, we’ve proven that the world’s most challenging problems can be addressed through frugal innovation. By embracing constraints as design drivers, focusing relentlessly on mission impact, and building systems that scale economically, we’ve created a blueprint for environmental engineering that other organizations can follow.

The Ocean Cleanup continues to demonstrate that in frugal architecture, less isn’t just more, it’s everything. As we work toward our goal of removing 90% of all floating ocean plastic by 2040, our success reminds us that the most elegant solutions often come not from having unlimited resources, but from making every resource count.

No one else was doing it or thought it possible. Thinking that it should be possible probably made me more qualified to do so than the experts who said it was mission impossible.

This mindset—that constraints breed innovation, that impossible is just another word for undiscovered—remains at the heart of everything we do.